Inhaltsverzeichnis

Altitude compensation with the Bing 64

…. or why the discussion about it always triggers a religious war…

… I say: the Bing type 64 carburetors, as installed in the Rotax aircraft engine, have no altitude compensation!

The discussion about this is always passionate. Unfortunately, you can often write what you want in the social media, it's probably not read properly or not understood intellectually or people don't want to go that deep.

That's why I'm trying to describe the topic here in as much detail as necessary.

...and what does Bing say?

Here is the technical note on adjusting the carburetor setting to atmospheric conditions:

The air density decreases with decreasing pressure and increasing temperature. If an engine is operated at a higher altitude, the weight of the air it draws in decreases air it draws in is reduced, while the amount of fuel drawn in remains practically unchanged. This results in a richer mixture than at lower altitudes: Depending on the sensitivity of the engine, a smaller or larger increase in sea level sea level, it is advisable to adjust the carburetor setting to restore the original mixture composition. mixture composition is restored. With increasing sea level and lower air pressure air pressure, the weight of the amount of oxygen drawn in by the engine also decreases. The associated reduction in performance cannot be compensated for by adjusting the carburetor setting. cannot be compensated for by adjusting the carburetor setting. Changing the main jet size is generally sufficient to adjust the carburetor. Only in special cases should a different needle jet and/or a different idle jet be selected.

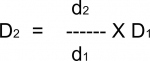

Assuming a nozzle size D1 at sea level d1, then

for sea level d2, the nozzle size D2 is calculated as follows:

Assuming a nozzle size D1 at sea level d1, then

for sea level d2, the nozzle size D2 is calculated as follows:

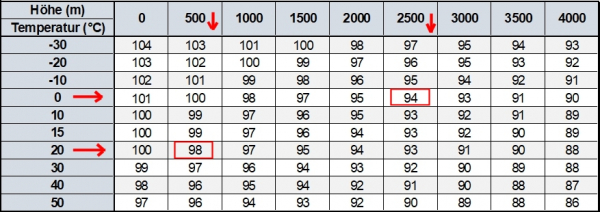

The adjacent table contains pure mapping values.

Example: If a motor is to be operated in Munich (sea level approx. 500 m) at a temperature of

temperature of +20º with a main nozzle 150 is to be optimally adjusted at the summit of the

Großglocknerstraße (sea level approx. 2500 m) at a temperature of OºC, a

the same mixture composition is achieved there with a nozzle 144.

Here is the original document to download as PDF

Here is the original document to download as PDF

How to use the table:

Let's take the example given and look for the values for our starting position.

The carburetors of the airplane are tuned to a sea level of 500m at 20°C intake temperature and equipped with 150 main jets. In the table, we find the value 98 in the column for the altitude at 500m and in the row for the temperature at 20°C.

We also find the value 94 in the table for the target of our carburetor tuning. Here at H = 2500m and T = 0°C.

Now the calculation using the formula: 94 divided by 98 times 150 equals 144.

This determines the main jet size as 144.

Unfortunately, this example is a bit off, because it is not exclusively about the height.

If we also calculate at an altitude of 2500m with 20°C (d2 = 93), we arrive at a nozzle size of 142.

Conclusion: With increasing altitude, the main nozzle must become smaller, otherwise the engine will enrichen.

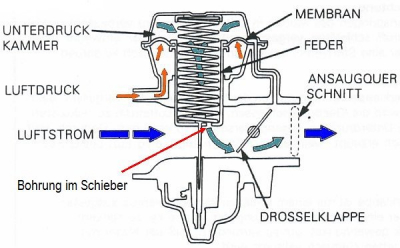

... but the Bing is a constant pressure carburetor!

… it is indeed and therefore equipped with a diaphragm.

You keep hearing the statement that you can already „somehow“ achieve a

height compensation, of whatever kind.

It is wrongly assumed that the diaphragm also ensures an adjustment of the mixture depending on the pressure in the Venturi tube (the narrowest point in the area of the nozzle block in the carburettor).

It is wrongly assumed that the diaphragm also ensures an adjustment of the mixture depending on the pressure in the Venturi tube (the narrowest point in the area of the nozzle block in the carburettor).

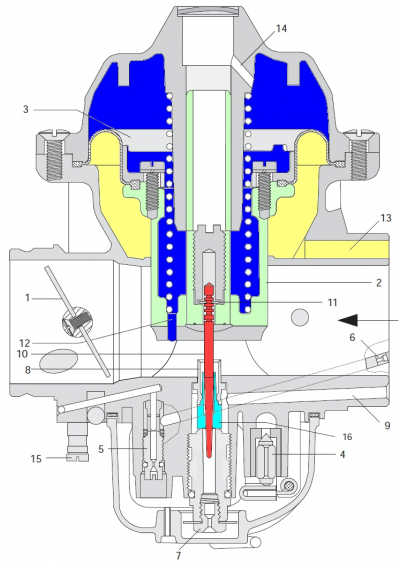

However, the function of the rolling diaphragm(3) is exclusively responsible for raising the carburetor slide(2) depending on the position of the throttle valve(1).

Raising the slide valve causes the cross-section in the Venturi tube to regulate the amount of aspirated air.

This raises the pressure difference between the ambient pressure(13) prevailing under the diaphragm1) and the negative pressure2) generated under the slide valve by the air flowing past the hole(12) in the intake manifold.

The amount of fuel sucked in through the nozzle block and limited by the main nozzle changes exclusively due to the pressure prevailing in the Venturi tube and exits at the atomizer(8).

…. but what does the amount of fuel added to the intake air in the nozzle block depend on?

In the Bing 64, this is done by

- the main jet

- the needle jet

- the jet needle

- the fuel level

- the pressure in the float chamber

The main jet measures the maximum fuel quantity from approx. 3/4 slide travel (the position of the slide piston depending on the power required by the throttle lever).

The needle nozzle and the nozzle needle form an annular gap in the mixing tube depending on the position of the slide piston and measure the fuel quantity in the partial load range.

The height of the fuel level in the float chamber, and therefore also in the nozzle block, causes the fuel/air mixture to become greasy or lean. Some people came into contact with this when the floats were no longer floating properly…

The pressure in the float chamber is regulated by the float chamber ventilation. Here it is important to place the end of the float chamber ventilation hose in a pressure-neutral location. If this is not observed, we have a major problem with the mixture preparation, as the smallest pressure differences have a very strong effect.

Here is the note from the Rotax WHB-Heavy:3)

NOTE:

The air pressure in the float chamber is crucial for the function of the

carburetor and must correspond to the air pressure before entering

the carburetor. Too high a pressure over-enrichen and

low pressure reduces the mixture, possibly to the point of

Stalling of the engine

Where is a control system here?

To say it up front : nowhere!

All the components described are always in a fixed relationship to each other.

Nowhere is anything regulated depending on the changing ambient pressure.

Bing describes a control with the change of the main nozzle. From one fixed value to another fixed value.

Possible regulation of the mixture

Aircraft with the corresponding equipment are referred to as Leanen.

However, the Rotax with the Bing's lacks such a possibility, as the carburetors are not designed for this.

What options would you have?

Basically any that leans the mixture.

I'll just list what I can think of.

- reduce the pressure in the float chamber

- reduce the float level

- make the main jet size adjustable

- supply air to the intake manifold behind the carburetor

… and for the first option there was even something to buy: the HACman Mixture Control, but the website is offline.

However, using the HACman Mixture Control means monitoring the mixture setting.

To do this, you could consult the exhaust gas temperature or install a Lamda probe with display.

However, this would be too dicey for me without appropriate test runs on a test bench where you can reduce the air pressure.

… in the sense

here's some reading (in German), found at Bing and discusses here diligently…

Addendum: I have deliberately not gone into the 914 Turbo here, because that is another, very complex topic.