Inhaltsverzeichnis

Differences between the carburetors for the 912 and 914

… are the carburetors not the same ?

…. of course not

Basically, we have three carburetor types depending on the design, which cannot be used for the different engines without further ado.

- Type 1 for the 80 hp engine 912/912UL

- Type 2 for the 100 hp 912S/912ULS engine

- Type 3 for the 115 hp engine 914/914UL

There is no difference between the certified and UL engines and their different versions.

There was also the 912ULSFR. However, this was only a version for the French market, which was absolutely identical to the 912ULS, only with blue valve covers. With the change in approval regulations in France, this version was discontinued.

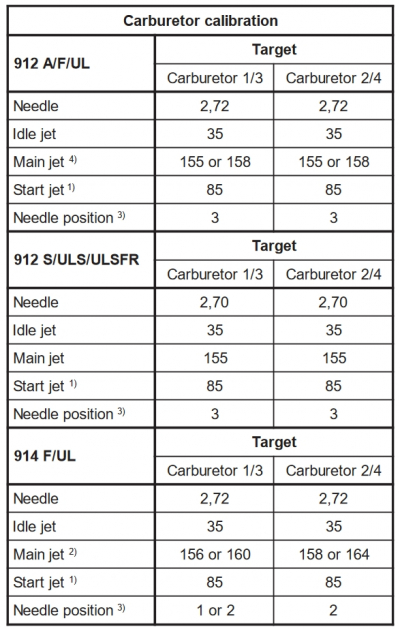

The jets of the carburetor

In the table, the needle nozzle is incorrectly labeled only with Needle….

The references to the corresponding service bulletins and service instructions must also be observed here.

This is particularly important for the 914, depending on the airbox version.

Differences between the carburetors

I will now disregard the different jetting and only go into the components.

The difference between 912/912UL and 912S/912ULS

There is only one different component here and that is the atomizer.

The 80 hp engine has a symmetrical atomizer (left). The upper end protrudes into the Venturi tube in a ring.

The atomizer can be easily removed during carburettor disassembly.

On the 100 hp engine, we have an atomizer whose tip is cut off at the side. It is mounted in the Venturi tube with the section towards the intake manifold so that it forms a „screen“ against the air flow.

This leads to a different pressure curve at the atomizer than with the closed atomizer. Therefore, it is not possible to swap the carburetor between the two engine variants.

The second difference is the knurling on the atomizer for the 100 hp engine.

This is required as an anti-twist device and ensures that the atomizer cannot fall out easily.

It is perfectly possible to convert the carburetor by replacing the atomizer and adjusting the jetting.

The difference between 912 and 914

The first noticeable feature is the float chamber, which is secured by a central nut and is only held in place by a bracket on the 912.

The reason for this is the system-related higher pressure in the float chamber. This must be absolutely tight for the turbo engine to run properly.

A Viton seal was introduced for this purpose. Since then, sealing the float chamber is no longer a problem.

The float chamber is pressurized with the airbox pressure via a hose system and a 3-way valve.

I will not go into the system any further here. A partial answer can be found here.

In the 914 carburetors, the symmetrical atomizers are also installed, as in the 80 hp variant.

The second difference only concerns the carburetor 2/4.

The throttle potentiometer required for turbocharger control is fitted here.

These carburetors could also be converted for the other engines.