Inhaltsverzeichnis

... always black spark plugs

… or why the spark plug pattern on a Rotax carburetor engine is usually a fata morgana…

There are often reports of permanently black spark plugs, especially in the 912 S / ULS, and puzzles about how to get the „problem“ under control.

If you ask further, you will eventually reach the point where it is explained under what operating conditions the engine was previously running and was switched off for the spark plug check.

When is the spark plug pattern checked?

The spark plug pattern is usually checked after a flight.

And there we have the salad. The flight ends with taxiing out and turning off the engine at the parking area.

If you now unscrew the spark plugs and look at the spark plug pattern, the insulator is pitch black or the spark plug patterns are completely different.

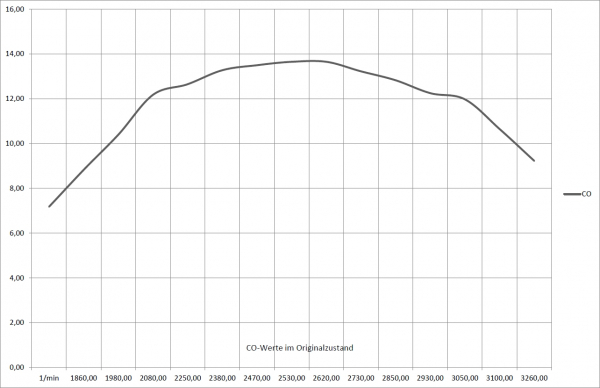

What is the reason for this? Let's first take a look at a graph that illustrates the CO content of the engine in the low to medium speed range:

If you now look at the speed range in which you roll to the parking area, it becomes clear that the spark plugs must be black.

With a CO content of approximately 14%, we are in a range where the engine is still just able to process the fuel „poured in“.

So we have to run the engine for several minutes in a range where the exhaust gas values are reasonably „normal“ before switching off.

But even here we are out of luck, because there are no „normal“ exhaust gas values for the Rotax that allow a meaningful assessment of the spark plug pattern.

One reason for this is that the intake manifolds have different lengths, the carburettors are not really tuned to the engine and the exhaust systems are designed „somehow“.

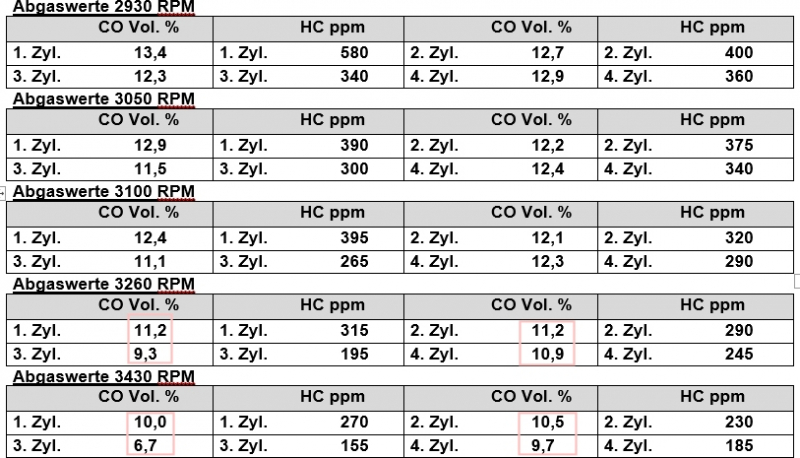

Furthermore, a detailed exhaust gas measurement will show that the exhaust gas values of the individual cylinders are approximately the same up to approx. 3200 rpm, but after that the values of the individual cylinders „drift“ towards each other, as can be seen below.

This means that at engine speeds above 3200 rpm, we notice a different spark plug pattern at each spark plug.

This means that at engine speeds above 3200 rpm, we notice a different spark plug pattern at each spark plug.

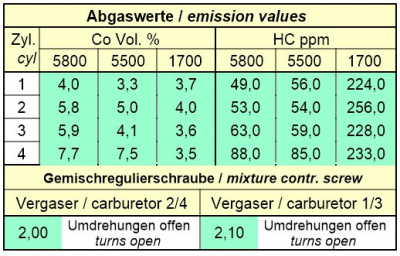

The following table shows this very clearly at 5500 rpm and 5800 rpm.

Here at 5500 rpm between 3.3% and 7.5% CO.

The adjacent table shows the exhaust gas values during an engine test run, measured on the individual cylinders. Here for a 912 S.

At 1700 rpm, the carburetors are set to the optimum values at idle on cylinders 3 and 4.

At 5500 rpm and 5800 rpm, the exhaust gas values are measured at full load and checked according to the manual to see whether the engine may be running too lean.

Conclusion

In the lower to medium speed range, the engine runs too rich for a reasonable spark plug pattern and in the upper range, the differences in the exhaust gas values of the individual cylinders are too large\….

So the spark plug pattern is only useful if there is something very wrong with the engine, such as heavy oil consumption or extreme lean running.

**If there is no suspicion of damage, you can forget about the spark plug pattern on Rotax carburetor engines during routine work.