Inhaltsverzeichnis

how to block the crankshaft correctly with the blocking screw

… and how to avoid dismantling the engine

Foreword

It wasn't just once that I had an engine on the „stretcher“ that had to be completely dismantled after routine maintenance.

The reason was usually a bent blocking pin in the crankcase that could no longer be unscrewed.

How does that work?

During engine maintenance, we come across the following maintenance point, which must be carried out every 100 hours:

As a rule, this check alone does not result in the locking pin being bent. However, this can happen if the gearbox is dismantled for the 1000h check and the drive wheel is loosened. When the nut on the crankshaft is loosened or tightened, such high forces are applied (200 Nm when tightening) that the pin bends if it is not seated in the notch of the crank web.

If it is necessary to lock the crankshaft, I recommend watching the following video from rotaxowner.com carefully. It is perfectly explained here:

why does the engine have to be dismantled ?

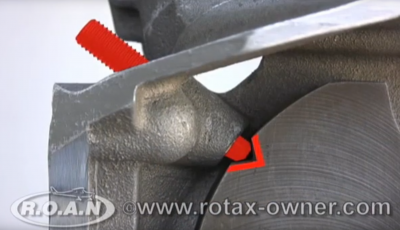

If the locking pin is not screwed correctly into the notch in the crank web, it may protrude into the engine housing next to the crank web when the drive wheel nut is loosened or tightened. As the distance between the threaded end of the hole for the locking pin in the housing and the crank web is greater than when the pin is properly seated in the notch in the crank web, we have a longer lever here. This may cause the end of the locking pin to bend in the crankcase.

If you now want to unscrew the pin, you can do this a few more threads and then it's over.

Now you can only unscrew the locking pin in the direction of the crankcase. This is usually only possible by dismantling the engine and separating the two halves of the housing.

This picture clearly shows how the blocking pin should be positioned

a trick

There is no tightening torque for the locking pin.

I recommend tightening it here with approx. 12 Nm - 15 Nm. You could also say hand-tight.

If you now think that the locking pin is seated correctly, there is another good control option.

Turn the locking pin out again 1/2 to 3/4 turns. Now place a finger on the locking pin and turn the propeller back and forth as far as it will go.

Of course, it should lock again in both directions after a very small angle.

At the same time, you should feel with your finger that the locking pin is moved back and forth a little when the notch in the crank arm touches the pin.

If this is the case, finally turn it hand-tight and you can now safely do what you have set out to do.

... what to do?

…. if the locking pin is bent after all?

To avoid causing even greater damage, everyone will probably remove the engine and send it to the distributor. This is basically the only option, as Rotax prohibits anyone other than a distributor or an authorized overhaul store from dismantling the crankcase.

the last attempt

begins with the fact that the blocking pin has been screwed all the way in and has now ended up in the crankcase.

With the engine still installed, you can now remove the cylinder head and cylinder #1.

Now take a magnetic lifter and fish past the piston in the crankcase for the culprit.

Once you've done that, you're done and can reassemble the cylinder and head ….

Conclusion

If you are not sure whether the locking pin is in the right place or not, it is better to unscrew it again and leave it to someone who is sure.