Inhaltsverzeichnis

The breakaway torque of the KW

Let's start the topic with a little history lesson.

Initially, the Rotax 912 was designed and built as an 80 hp engine.

It worked well and there were few problems. Even when the first 914 Turbo's were built, which is just a blown-up 80 hp engine, it stayed that way.

Now came the 912 S / ULS with 100 hp.

The displacement and compression were increased and the timing was tightened.

Basics

You can imagine that, depending on the operating conditions, the piston side forces introduced into the crankcase via the cylinder wall increased significantly.

For clarification, the distribution of forces is described here and labeled in the figure as the force Fn.

The increased piston side forces caused movement in the engine housing at its parting surface (the crankcase is divided vertically) and consequently wear in the area of the crankshaft main bearings. This will follow in more detail.

To avoid this, Rotax had published a service letter for adjusting the performance.

Here you can read in the SL-912-016 / SL-914-014 from 2009:

Performance recommendations

| Step | Procedure |

|---|---|

| 1 | Engine speed above 5500 1 /min is limited to a maximum of 5 min (as specified in the 912/914 series operating manual). |

| 2 | Starting speed at WOT (fully open throttle) should not be below 5200 Ilmin to avoid overloading the engine. |

| 3 | Continuous use of engine speeds below 5200 rpm with WOT should be avoided. |

The fact is that the piston side forces are lower at higher engine speeds due to the decrease in combustion pressure in the critical range, which consequently leads to less force being applied to the crankcase. Among other things, this is related to the combustion speed of the ignited fuel-air mixture.

I found a very clear video on this here.

The damage

Now the following damage occurred in the crankcases:

In the area of the main bearings, the two crankcase halves permanently shifted relative to each other in the nanometer range due to the forces applied. The resulting friction led to wear and abrasion on the separating surfaces, which in turn led to a reduction in the bearing clearance of the main bearings.

As the wear progressed, the bearing clearance decreased until there was none left.

The result was that the crankshaft became increasingly difficult to turn

At some point, as the process progressed further and further, the starter was no longer able to turn the crankshaft because the breakaway torque was higher than the force supplied by the starter to turn it.

Many pilots / maintenance personnel did not notice this at first, especially as there was nothing about it in the maintenance manuals.

It was only later that a checkpoint was added to the maintenance manuals.

Suspicion

… but what does „in case of suspected HEAVILITY“ mean?

When you turn the propeller, the following behavior is observed:

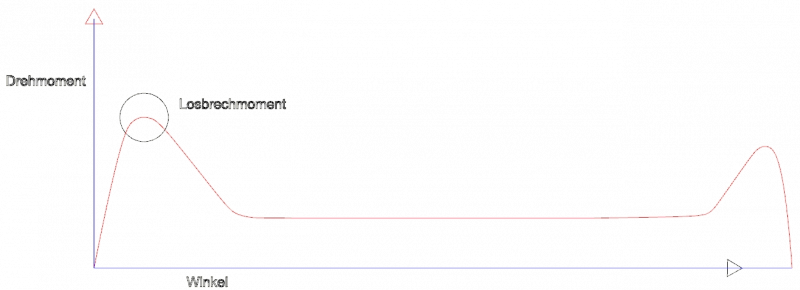

Initially, the breakaway torque is manifested by increased resistance when you try to turn the propeller. If it rotates, we feel a lower and more even effort. If you now stop the rotation, you will notice a jerky stop of the propeller. This is roughly illustrated by the following curve.

Need for action

150 Nm

… that's quite a house number…

If we take into account the gear ratio of 2.43:1 for the 912 S/ULS, this means a breakaway torque of 61.73 Nm at the crankshaft.

If a breakaway torque of over 15 Nm is detected on the crankshaft of an engine during maintenance and it is subsequently disassembled, the typical rough, gray discolored areas can be seen in the area of the main bearings on the housing interfaces.

Measurements of the remaining crankshaft bearing play would show a play of 0 (ZERO) or less.

Is also logical, because otherwise we would not have an increased breakaway torque of the crankshaft.

Consequence

…. and the moral of the story:

do not overload the engine

But managing this1) is not a problem. You fly diligently with WOT at reduced speed and a new motor housing is not far away…

the new ones

In the meantime, the crankcase screw connections have been modified several times, so that the surface pressure in the parting line could be significantly increased and the problem was basically solved.

However, there are said to be users who have nevertheless buried a housing in this way….