Inhaltsverzeichnis

Lubrication of the hollow propeller shaft

… how the propeller shaft and the longitudinal gearing are lubricated without contact.

We basically have two types of gearbox:

- with a hollow propeller shaft for a fixed pitch propeller (version 2)

- with an oil channel for a hydraulic governor (version 3)

Version 3, for the hydraulic governor, has a 1mm lubrication hole in the area of the longitudinal gearing, so that the longitudinal gearing, and thus also the driver for the slipping clutch, is lubricated with engine oil.

Normally, in version 2, i.e. with the hollow propeller shaft, the lubrication of the longitudinal gearing is not particularly good, but is actually sufficient.

The prerequisite is that a sufficient oil temperature is reached.

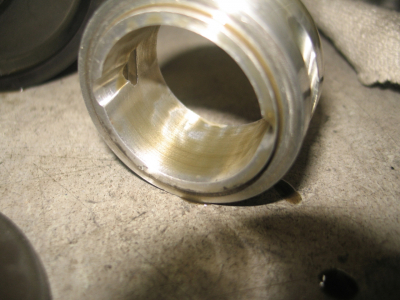

If we have a so-called „cold runner“, the gearbox may look like this after disassembly:

cruel pictures

This is caused by the oil temperature being too low during operation, resulting in an increased build-up of condensation in the engine and the formation of rust on various parts after the engine has been switched off. The crankshaft and propeller shaft are particularly affected. If the crankshaft starts to rust a little on the crank webs, this does not interfere with operation. The propeller shaft looks like the one in the pictures.

With the introduction of the 912iS injector, the problem became even worse, as the engine runs much leaner and we have less fuel condensate in the crankcase, which means a loss of lubrication.

At some point, Edi (Eduard Franz) came to me and said that we had to do something about it - it couldn't go on like this….

His suggestion was to design a pressure lubrication system that could be placed in the area of the eccentric and the spacer sleeve on the injector. However, this would mean that the lubrication could not be installed in the carburetor engines, as the eccentric drives the mechanical fuel pump.

the design

My idea was to realize the lubrication without contact.

No sooner said than done.

After extensive consultation, Edi turned a suitable sleeve and I made a spray nozzle, which was mounted near the hole for the fuel pump and fed from the pressure line connection for the hydraulic governor.

After extensive consultation, Edi turned a suitable sleeve and I made a spray nozzle, which was mounted near the hole for the fuel pump and fed from the pressure line connection for the hydraulic governor.

A smoking colleague had to blow into the connection to adjust the oil jet.

Tests

The results on the test bench were surprisingly successful.

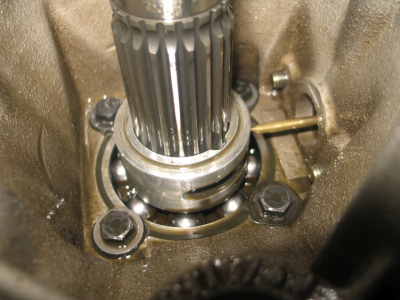

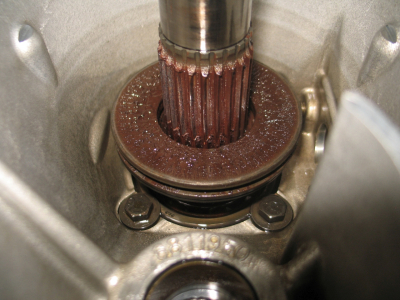

The gearbox was completely dry, i.e. degreased with brake cleaner, mounted on a 912iS injector and a test run of 5 minutes was carried out.

This is what the components looked like after disassembly.

Even in the slipping clutch, the friction plates were wet with engine oil.

the principle of lubrication

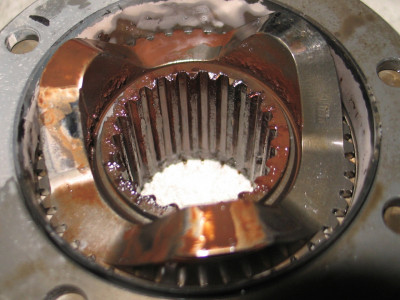

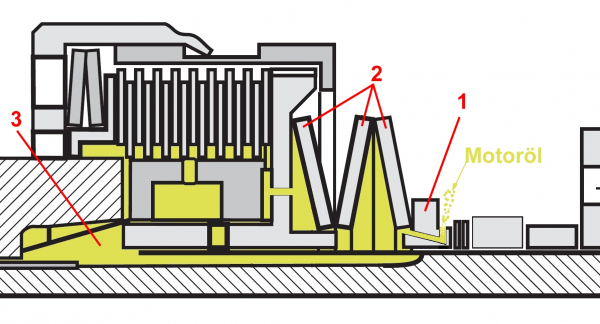

The engine oil that enters the slotted stepped sleeve(1) through the spray nozzle is conveyed towards the slipping clutch via the disk springs(2) by the centrifugal force generated by the rotating propeller shaft and fills the entire cavity(3) next to the propeller shaft.

In addition to the well-lubricated longitudinal gearing and the slipping clutch, we also have the effect that the disk springs hardly wear at the contact surfaces and the claw ramps are better lubricated.

what Rotax has done with it

1st picture: Prototype of the stepped sleeve - 2nd and 3rd picture: The final shape.

Rotax finally brought the project to series maturity and designed the stepped sleeve accordingly.

Rotax finally brought the project to series maturity and designed the stepped sleeve accordingly.

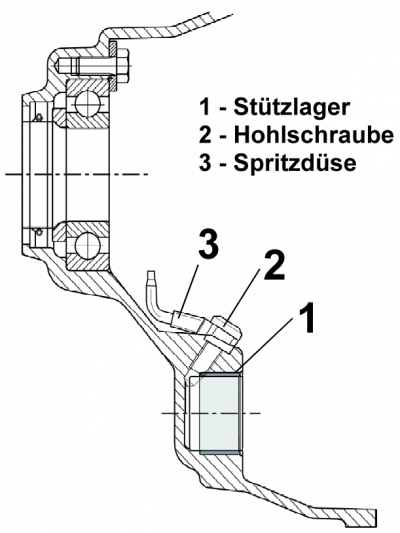

In addition, the gearbox housing was fitted with a spray nozzle that is fed by the crankshaft support bearing in the gearbox housing.

The oil pressure of the crankshaft lubrication was utilized here.

The new gearbox housing now has the spare part number

811957 for the 912 and 914 carburetor engines

811959 for the 912iS injection engine

This also indicates whether the gearbox is equipped with the lubrication system.

- crank shaft bearing

- banjo bolt

- spray nozzle