Inhaltsverzeichnis

Check the oil level correctly

A short guide on how to check the oil level in the oil tank correctly.

First a recommendation from me:

The oil level should be checked in the hangar immediately after the flight.

The reason should be obvious: the engine oil always has approximately the same temperature and the aircraft is always in the same position. Another advantage is that the engine oil is naturally thinner and can therefore flow more easily from the crankcase through the blowby gas into the oil reservoir.

Unfortunately, there is an important limitation here: the procedure should only be used if the glider is only flown by one person at a time.

With a club or several pilots, unfortunately one person does not know what the other is doing …

In this case, check before the flight.

The Operation Manual says the following:

| Step | Procedure |

|---|---|

| 1 | Check the oil supply and top up if necessary. |

| 2 | NOTE: the propeller should not be turned against the normal direction of rotation. Open the oil tank cap. Turn the engine a few turns by hand on the propeller in the direction of engine rotation to pump the oil from the engine into the tank. |

| 3 | It is important that the compression pressure is built up in the combustion chamber. Keep the pressure up briefly so that the gases can enter the crankcase via the piston rings. The rotational speed is not decisive, but the pressure and the amount of gases that enter the crankcase. |

| 4 | The process is complete when air also flows back into the oil tank. This can be detected as noise (gurgling) when the oil tank cap is open. |

| 5 | Close the oil tank cap. |

The question often arises as to whether or not the oil dipstick should remain in the oil tank when the engine oil is pushed back when turning.

It doesn't matter at all, as you should always wipe off the dipstick before checking.

How is the prop turned?

Unfortunately, there is no precise description of how to turn the propeller correctly.

The manual says:

It is essential that the compression pressure is built up in the combustion chamber.

Maintain the pressure briefly so that the gases can enter the crankcase via the piston rings.

The rotational speed is not decisive, but the pressure and the quantity of gases that enter the crankcase.

Aha —

Now it gets exciting, because we have a 4-stroke engine and not a rubber powered engine - or maybe we do ?

If you watch the pilots and don't know that he is currently pumping the engine oil into the oil tank, you might think he is just winding up the rubber engine for the plane. Or maybe it has a spring starter like the COX model engines?

The basis

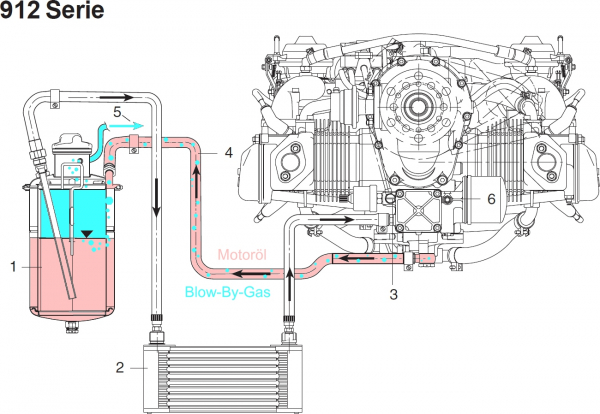

We have dry sump lubrication in the Rotax. In normal engine construction, this means that we have an extra oil pump for pumping the engine oil from the crankcase into the separate oil container or oil tank.

In the Rotax, the 2nd oil pump has been dispensed with and the crankcase ventilation is used to return the engine oil via which the Blow-By-Gas hissing past the piston is discharged.

In normal car engines, this can no longer be done for environmental reasons. There, the crankcase ventilation is fed back into the intake tract and the oil vapors are burned.

Here is a schematic representation of the return of the engine oil on the Rotax 912.

How do you generate enough blow-by gas to pump the oil from the crankcase into the oil reservoir when the engine is not running?

I have already blasphemously said that most pilots simply turn the propeller as if they had to „wind up“ the engine.

But in doing so, they give away the painstakingly built-up pressure in the combustion chamber at TDC (Top Dead Center).

If anyone has paid attention during the routine pressure loss test, they must have noticed that there is always at least 4% - 5% pressure loss.

And this pressure loss is exactly the blow-by gas we need.

This means that when turning the engine in the combustion cycle at TDC, you should take a short break to wait until the pressure built up in the combustion chamber has diluted into the crankcase.

A slight overpressure is then created there, which escapes from the crankcase ventilation/oil return line and takes the oil in the crankcase with it.

Conclusion

Turn the engine with the propeller until the resistance of the gas compressed in the combustion cycle restricts the rotational movement as much as possible.

Stop the rotation of the propeller for a few seconds and wait until the pressure in the combustion chamber has been released.

Now turn to the next combustion cycle as quickly as possible and compress the gases in the combustion chamber again.

In this way, you move from TDC to TDC until there is a good gurgle from the oil tank.

I recommend repeating this process three times, as this leaves a sufficiently small amount of engine oil in the engine crankcase.

…. which I had completely forgotten and was pointed out in the social media: of course you now have to check the oil level with the dipstick and top it up if necessary.

**Note: I have written some further thoughts on this at here.