Center the throttle valves of the Bings

… an often unnoticed mistake during a carburetor repair

Basics

Normally, you can assume that factory-assembled parts work perfectly.

They usually do, but I have my own opinion about the bings:

… don't trust a Bing that you haven't assembled yourself!

This is where the throttle valve comes into play, the correct position of which I will now discuss and which is not always perfectly fitted at the factory.

In the article on the purpose of the transition bores, I discussed the engine running of Rotax carburetor engines in the transition area.

It should be noted that if the throttle valve is not correctly centered, you can adjust and synchronize the carburetors as you like, but you will still not get a reasonable engine run in the transition area.

Influence

If the throttle valve is not correctly centered in the lower area of the carburetor, i.e. in the area of the transition bores, when it is completely at the stop (i.e. at idle), the engine will seize up more due to the increased clearance of the transition bores.

Even if you only accelerate a little and the engine is running between 2000 rpm and 2500 rpm, any gap, no matter how small, is noticeable. It is therefore necessary for the throttle valve to be completely closed in the area of the transition bores when the idle stop is fully unscrewed.

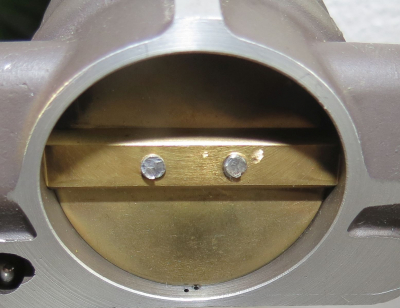

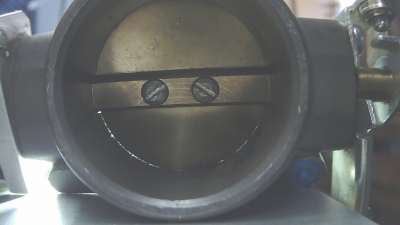

In the picture1) you can see these transition holes very clearly.

Check

First, the carburetor should be disassembled and clean.

Then the throttle valve spring is repositioned so that the throttle valve is pulled to the idle stop, i.e. it is spring-loaded closed.

Now unscrew the idle stop until a clear gap is visible between the adjusting screw and the stop.

This can be seen clearly in the top right-hand corner of the following two pictures.

If you now look into the carburettor from behind 2), you can see the possible air gap if you look at the throttle valve from the front 3).

If no gap can be seen in the area of the transition holes4), the setting is OK and nothing needs to be done.

Adjust

The two screws of the throttle valve are caulked at the factory.

This means that the slots for the screwdriver are no longer really usable. On the other side, the end of the screws is mushroomed so that the thread in the throttle shaft would be damaged when unscrewing the screws.

However, the slots in the screws can be made wide enough to allow the screws to be unscrewed.

The good thing is that you only have to loosen the screws by about 1/2 a turn to be able to move the throttle valve. It is also not necessary to machine the protrusion of the thread on the other side.

If you need or want to replace the O-rings on the throttle valve shaft, grind off the caulked protrusion of the screws at this point using a Dremel or rod grinder until the screw ends are flush with the shaft. The screws (P/N 941200 SLOTTED HEAD SCREW M3x6) should now be replaced and secured with LOCTITE 603.

The slot can be widened again with a good and suitable slotted screwdriver by „scraping“ it open piece by piece with the screwdriver blade.

If the screwdriver fits into the screw slot again, you can now loosen it 1/2 to 3/4 turns until the throttle valve can be moved in the slot of the shaft.

Centering is now very simple:5)

you open the throttle valve a little with the throttle lever and simply let it „snap back“ into its original position by the spring force of the throttle valve spring.

If you are lucky, you will no longer see a light gap in the area of the transition holes - then the work was successful and you can tighten the two screws again.

If a light gap is still visible, repeat the whole process until it fits.

Note

When should the O-rings on the throttle valve shafts be replaced?

If you move the ends of the shaft radially and you notice any play.

There is only one reason to replace the O-rings and that is if secondary air can be drawn in via the throttle valve shaft.