Inhaltsverzeichnis

Permanent oil pressure fluctuations during operation

… when the needle trembles or the numbers do not come to rest

Depending on the oil pressure indicator installed, there is this problem, which has been excellently described in the UL forum:

… I have recently noticed a very rapid change in oil pressure at certain engine speeds on a warm Rotax 912 ULS (approx. 600h).

At certain engine speeds, the oil pressure fluctuates several times within a second in the range of approx. 3.7 to 5.8 bar.

I gave the following answer:

The oil pressure fluctuations are unfortunately a result of resonances in the design of the oil pump and the oil pressure control valve and cannot be brought under control unless the entire oil circuit outside the oil pump is changed.

However, this is in the hands of the aircraft manufacturer. Unfortunately, there is no guarantee that it will not occur again after a change.

By installing the mushroom-shaped valve piston (857230), an improvement can possibly be expected but is not certain.

However, as these resonances have never caused any damage to my knowledge, I recommend simply ignoring them or installing a more heavily damped instrument.

That was very brief and is actually the complete explanation for the occurrence of oil pressure fluctuations in the oil system of the Rotax aircraft engine.

In the cockpit, however, it always leads to astonishment and, above all, to uncertainty among pilots - especially if they have not seen it before.

For a better understanding, the whole thing now follows in a little more detail.

The oil system

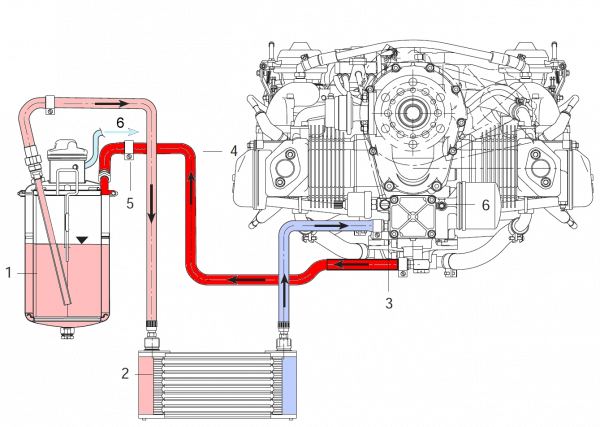

Let's first look at the dry sump lubrication system used on the Rotax.

Let's first look at the dry sump lubrication system used on the Rotax.

In contrast to wet sump lubrication, in which the engine oil is stored in the engine block, usually below the crankshaft in the oil pan, this requires a separate oil reservoir(1). We are all familiar with this, as this is where the engine oil is topped up if necessary.

In a standard dry sump lubrication system, a double oil pump is used to return the engine oil dripping into the crankcase after the lubrication process to the oil tank.

In the Rotax, this was realized much more simply and, above all, much more easily by using the Blow-By-Gas that is always present in the combustion engine to return the engine oil. For this purpose, the engine does not have an extra crankcase ventilation system, but the „misused“ oil return line(4). The crankcase ventilation then takes place at the oil reservoir(6). Proof of this process is the „burping“ from the oil reservoir when the engine is turned over by hand to check the oil level.

The oil intake side

Somehow, the engine oil has to get from the oil tank to the oil pump. This happens through the suction line.

It starts at the oil reservoir and leads via the oil cooler to the inlet side of the oil pump.

The requirements for the oil line defined in the installation manual look like this for the 912:

Usually, oil-resistant hoses are used for this purpose, which are not contracted by the resulting suction power of the oil pump.

And the elasticity of the hoses is the reason for the oil pressure fluctuations.

The oil pump

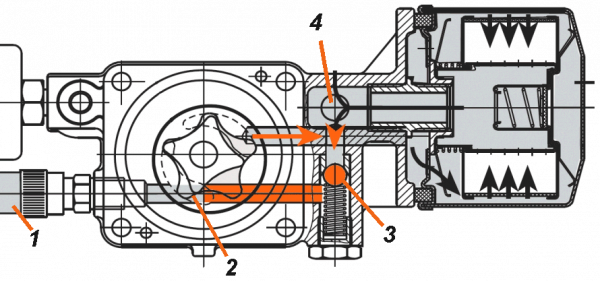

To explain the pressure fluctuations, we now need to take a closer look at the oil pump.

- Here is the oil supply line connected to the oil pump

- Here is the inlet to the intake side of the trochoid in the oil pump

- the oil pressure control valve

- the oil channel for engine lubrication and the oil pump outlet

Basically, such an oil pump, whether a gear pump or a Eatonenpumpe, has a very high delivery pressure.

Basically, such an oil pump, whether a gear pump or a Eatonenpumpe, has a very high delivery pressure.

This must be reduced/regulated and this is achieved by the oil pressure control valve. The excess oil „regulated“ by the control valve is usually discharged into the engine oil pan.

… but not with the oil pump of Rotax aircraft engines

Here, the oil is fed directly back into the oil supply through the channel shown in red.

This has two advantages: 1. the amount of oil to be drawn in by the pump is considerably reduced, as only the oil required for lubrication has to be drawn in and 2. it reduces the amount of oil that has to be returned to the oil reservoir, which could potentially be difficult with the blow-by gas.

The disadvantage

The oil return channel after the oil pressure control valve is absolutely the same as the oil inlet from the oil reservoir. This means that when oil is regulated away from the valve, it flows exactly opposite the oil coming from the oil reservoir.

Depending on the oil temperature, delivery rate and pressure of the oil pump and the elasticity of the oil hoses, this can lead to resonances in the entire oil circuit. How the condition is caused is not yet entirely clear to me, but is probably caused by the control behavior of the oil pressure control valve.

As I have already written, the installation of the mushroom-shaped valve piston (857230) could possibly lead to an improvement.

However, experience has shown that in most cases only the resonance frequency has shifted.

What now?

The result of resonances now leads to the oil pressure fluctuations described, mainly with electronic instruments that have a certain measuring interval. They then show the pressure sometimes on the mountain and sometimes in the valley.

Well-damped analog instruments only show a comfortable calmness here - namely no fluctuations.

Conclusion

**Close your eyes and go for it!

There may be ways to remedy the situation. However, this is a matter for the aircraft or instrument manufacturers.

Damage is not to be expected - at least I'm not aware of any.

I once had the same problem with the fuel gauge on my beloved NSU TT. The instrument had zero damping, so it showed every up and down movement of the float. This even caused the pointer in the instrument to rattle at the stops when the fuel level was below 1/4 or above 3/4.