Replacing the float needle valve seat bushing

Again and again you hear that the carburetors overflow at standstill because the aircraft

Again and again you hear that the carburetors overflow at standstill because the aircraft

is a taildragger.

This is wrong.

The Bing carburetors come from a BMW motorcycle and are therefore designed for high acceleration and deceleration values.

If fuel drips from a carburetor when stationary, it is most certainly not due to the inclination of the carburetor.

…. As always, problems usually start quite harmlessly:

one morning there is a small stain under the plane. Cooling water ? Engine oil ?

After the finger test you are sure: engine oil, because it is so greasy.

Cowling down, flashlight search and lo and behold, the engine is completely tight - or just as leaky as ever.

Must have been too much oil in the oil tank - then it just drips out of the breather hose.

After weeks in which there was always a small stain on the floor, then the surprise:

It stinks of fuel in the hangar and there's a huge pool of fuel under the plane.

How is that supposed to work, they did a 200h check a week ago and, as a precaution, installed new float needle valves to possibly banish the strange stains under the engine.

…. and here it comes: Carburetor checked 3 times and constantly the same game with the overflowing carburetors 1).

Anyone who was lucky enough to come across this post in the UL forum will perhaps remember similar pictures:

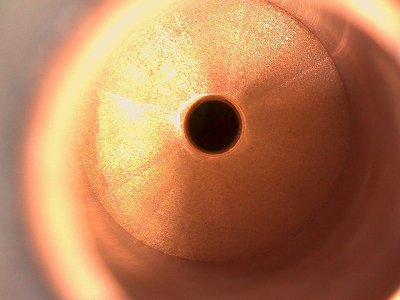

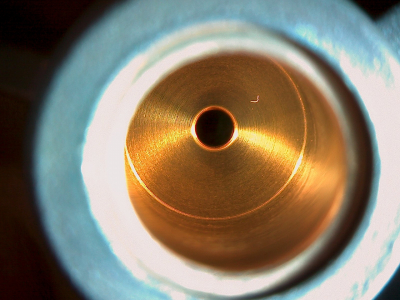

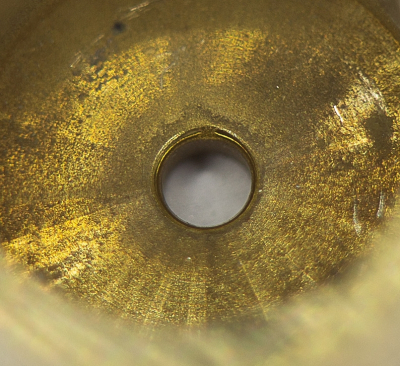

Float needle valve seats under the microscope

– the first picture was taken after 120 operating hours

The third picture is by © Steffen E. and is a very clear example as a supplement to his post in the UL forum.

The advice obtained from the trusted Rotax dealer is devastating: Replace carburetor - price = 4 digits.

But now you can resort to a repair method not approved by Rotax. Replace the valve seat bushings.

You can order them --here-- and replace them relatively easily with the --self-build tool--.

Carry out the work as follows:

- Remove the overflowing carburetor and disassemble it completely,

- use an M8 tap to cut a thread in the bushing,

to do this, grease the front of the tap properly to catch the chips - Screw the screw of the tool with the nut and the extraction bushing into the valve seat and pull the valve seat bushing into the tool

- flush the fuel inlet with brake cleaner, blow it out and check for swarf

- sparingly wet the outside of the new valve seat bushing with Loctite 221 or 243

– Loctite is used as a lubricant and for sealing - Press in / hammer in the bushing with the insertion tool

- Install the float and float needle valve

- Adjust the float level with --Gauge--

- Complete and install the carburetor and synchronize the carburetors

You should now have some peace and quiet for a while…..