Inhaltsverzeichnis

The transition holes

Foreword

I struggled with myself for a long time whether I should publish this topic or not, because I don't want to be responsible if someone does what is described on his plane, lands in the field and then (he or his survivors) points his finger at me and says:

„…. but he showed me that“.

That's why I'm saying very clearly here:

Don't do that, don't modify the carburetors illegally!

…. That's why I'm only reporting here on my experiences with modifying the Bing's on a 912 ULS with 100 hp.

IMPORTANT: the modification has now been extensively tested on the 914 Turbo!

You can therefore assume that it works in the same way on the 912 with 80 hp, as the engines are identical except for the turbocharger and the associated stuff.

…. almost more important: this work is not for beginners !!!

Basics

It is well known that the 912 S/ULS in particular runs very rich in the range between 2000 - 2500 rpm, which can also lead to rough engine running.

With increasing operating hours, the behavior of the engine usually deteriorates in this range.

Now the Bing's come from a motorcycle with 2 cylinders and behind each carburetor is a relatively large single displacement.

In the Rotax, one carburetor supplies two, somewhat smaller, cylinders with ignitable mixture.

You can imagine that there are therefore completely different flow velocities in the carburetor. Furthermore, on a motorcycle, you need to quickly enrichen the mixture in the transition after idling so that the bike does not stop at the traffic lights when you open the tap.

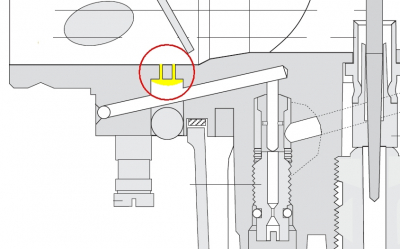

This is why the Bing has two transition holes near the throttle valve, which allow additional fuel to enter the intake tract when the throttle valve is opened.

Does the Rotax need this?

… that can be answered with a clear NO!

- The gas flow in the carburetor is relatively even,

- an aircraft engine does not usually accelerate suddenly like a motorcycle,

- the Rotax already runs quite rich at idle anyway,

- unlike a motorcycle, the load on the engine only increases with the air resistance of the propeller.

The last sentence also shows that we only find a uniform increase in the gas flow velocity in the carburetor.

There is no need to take sudden power delivery into consideration.

Original

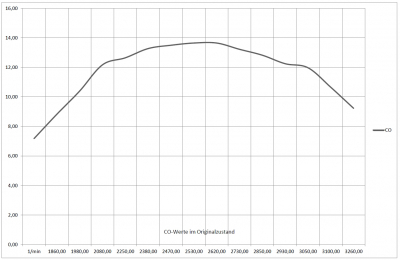

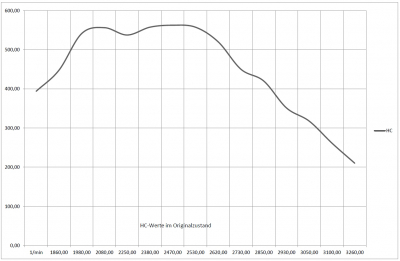

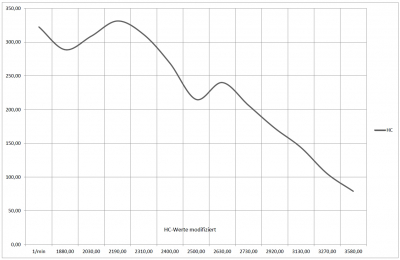

This is why we have the following exhaust gas values (values determined on the test bench with overhauled carburetors) for the Bing's in their original condition (left CO - right HC):

click to enlarge

At almost 14% CO and 550 ppm HC, the engine is already running very close to the „stall limit“.

and forgery

Since I was able to gain some experience with carburetors during my almost 30 years as a motorcycle mechanic, I have now sealed the transition bores on a set of used Bing's.

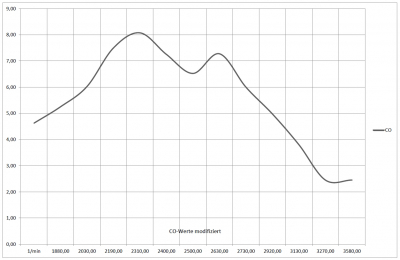

Subsequent test runs with extensive exhaust gas measurements and also tests with sudden throttling in every operating state then resulted in the following pictures:

…. looks great, I thought to myself and looked for a test pilot ….

I found someone who I knew had expertise and was an experienced pilot.

Unfortunately, such a field test is not without risk.

He has now (as of summer 2023) flown around 1200 hours with it and said that he would never give the carburetors back under any circumstances.

He has changed or serviced absolutely nothing on the carburettors in all this time - also to see what happens with increased wear on the usual components: runs and runs and runs and runs and runs ….

…. in the meantime, he said he would have to do something soon….

The idle mixture had to be adjusted a little richer and when it's cold, he has to use the choke a little longer.

However, the unclean engine running at low revs is completely gone and long flights with „drag throttle“ are not an issue.

The latter is a problem for many pilots when they „starve“ themselves the last few meters to the runway (why isn't it called „Hunger gas“?).

My test pilot had to practise this first, as he normally plunges quite steeply onto the runway….

modify

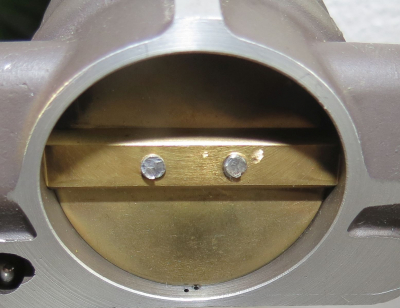

… and this is how I did it:

- removed the float chamber from the carburetors

- removed the idle jets and mixture screws

- flooded the holes of the idle jets with brake cleaner and blew them out

– so that the idle system is dry and grease-free – - a little 2K-Stabilit Express 1)

- and glue the transition holes.

- When gluing, make sure that not too much adhesive gets into the transition holes, otherwise the channel in the carburetor will be closed. The carburetor can then only be saved with considerable effort.

- The excess glue is simply cut off with a scalpel in the Venturi tube with the throttle valve open while it is still not fully cured.

If the transition holes have been sealed, the basic setting of the idle mixture screws is approx. 2.0 to 2.5 turns.

I recommend finally adjusting the mixture using the speed method.

Picture story

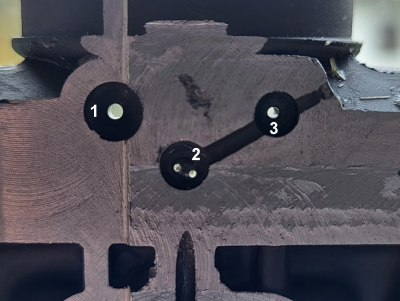

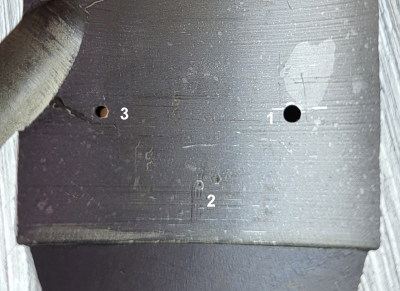

1=Synchronization connection 2=Transition holes 3=Hole for idle mixture adjustment screw and outlet of the idle mixture in operation