Inhaltsverzeichnis

the hoses of the float chamber ventilation

… on the 914 and their pitfalls.

The system

First a few basics on how a supercharged combustion engine with a carburetor works.

A carburetor can only deliver the right mixture if there is a certain pressure ratio in the jet systems.

The ratio between the intake manifold pressure and the ambient pressure plays a significant role here. In principle, the nozzle sizes are determined and adapted for a defined ambient pressure. As a rule, this is the pressure at sea level. With a non-turbocharged engine, the air pressure in the float chamber drops with increasing altitude and the engine runs richer and richer. This is logical, because that's what float chamber ventilation is for.

With a turbocharged engine, we have a considerably higher pressure in the intake manifold, i.e. also in the carburetor jet systems.

In order to create the correct pressure difference in the carburetor despite this, the float chamber ventilation is simply connected to the airbox and thus the correct pressure difference is restored.

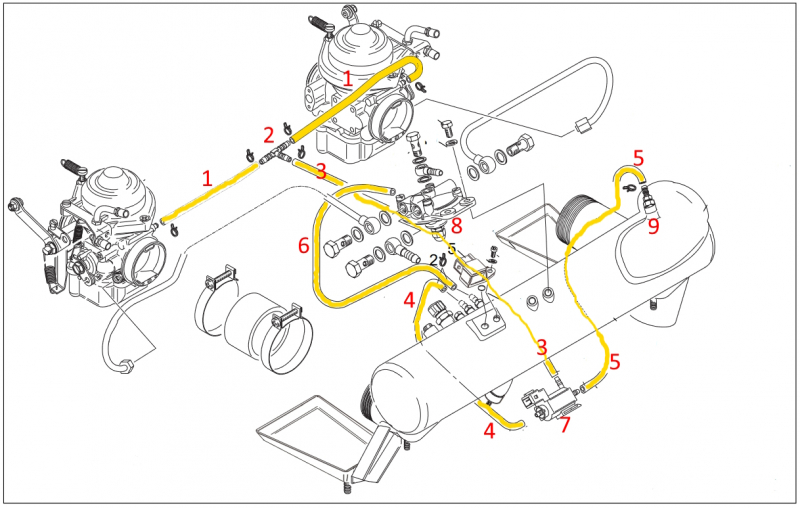

On the Rotax 914 it looks like this:

The description

A hose(1) is fitted to each float chamber ventilation, which leads via a T-piece(2) into the individual hose(3) to the 3-way valve(7).

If the airbox pressure is below 1280 mbar, the hose(4) leads from the 3-way valve to the middle of the airbox.

If the airbox pressure now rises above 1280 mbar, the 3-way valve switches over. As a result, the pressure for the float chamber ventilation is now removed via the hose(5) from a pitot tube(9) in the air flow of the air pressed into the airbox by the turbocharger.

Due to the position, design and setting of the pitot tube, the pressure in the float chamber is increased by 10 mbar. This means significant greasing at a power setting of 115%, i.e. starting power.

We also have the hose (6) that leads from the center of the airbox to the fuel pressure regulator. The fuel pressure regulator regulates the fuel pressure to 250 mbar via the airbox pressure.

This is necessary because the same pressure difference must always prevail at the float needle valve so that it can reliably regulate the fuel level in the float chamber. The closing pressure at the valve tip plays a role here.

This increases with increasing pressure in the float chamber and the fuel level drops, resulting in lean fuel. This happens if the fuel pressure regulator is defective and supplies too low a fuel pressure.

Cracks in the hoses

This is only caused by damage due to carelessness.

If the hoses are replaced during the prescribed 5-year inspection, there are never any cracks or porosity due to age.

The most common cause is the hose being bumped against the side of a connection nipple by a solid object. This squeezes the hose and causes a mostly invisible crack to form. Furthermore, the hoses are often overstretched when they are pulled off a connection nipple and tear.

Defective 3-way valve

If the 3-way valve no longer switches over, this only affects the starting performance.

You will notice an unwilling throttle response and an unsteady engine speed that does not rise to the usual level.

The mixture is not enriched as required for starting performance.

Defective fuel pressure regulator

Here we have more gradual symptoms. If the airbox pressure rises due to the required performance, the mixture slowly leans out.

We have increasing pressure in the float chamber but there is no back pressure from the fuel. This means that the closing pressure at the Viton tip of the SNV2) increases and it tends to close the inlet.

The fuel level becomes lower and the engine runs leaner. This can lead to engine damage because it is not necessarily noticed, depending on the remaining control capacity of the pressure regulator.

Crack in hoses 1, 3 and 4

This is usually noticed immediately.

The engine revs up normally up to approx. 4500 rpm and then immediately starts sawing3).

The more throttle you apply, the worse it gets. A flight is therefore not possible and should not be considered.

Crack in the hose 5

Is almost the same as a defective 3-way valve, only in a weakened version.

It is also possible that the defect is not noticed and there is an „unhealthy“ leaning of the engine at starting power.

Engine damage would then be possible.

Crack in the hose 6

This is almost the same as a defective fuel pressure regulator.

Incorrectly adjusted pitot tube

The correct position is important for the full-load enrichment system.

The pitot tube has a hole that is directed into the airflow that is fed from the turbocharger to the airbox.

Incorrect adjustment can lead to engine damage due to leaning.

If the pitot tube is twisted, there is a basic setting as shown in the following illustration.

An exact setting is only possible on the engine test bench and is carried out after a repair during the test run.

This requires an exhaust gas measurement at starting power.

The lock nut of the pitot tube is marked in color with locking paint.

If the paint is damaged, help from a competent (who knows what he is doing) mechanic is required.